Products Details

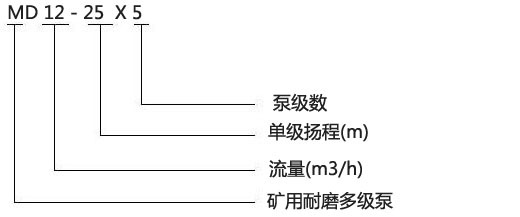

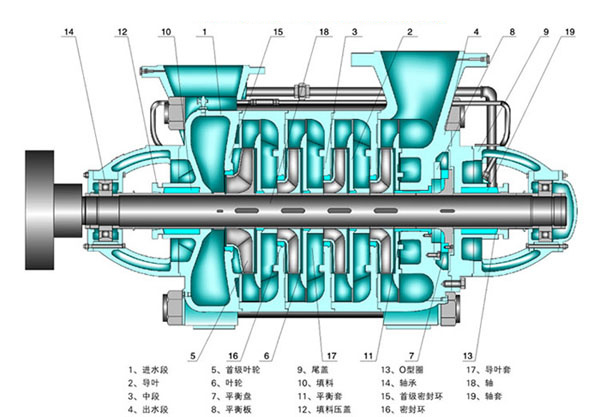

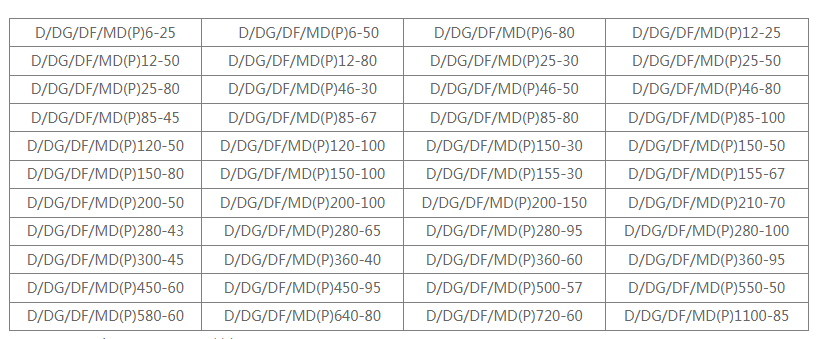

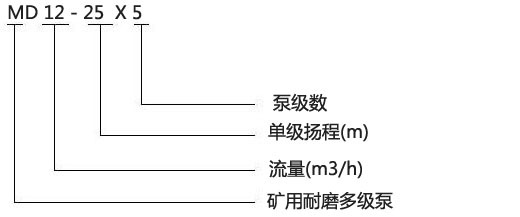

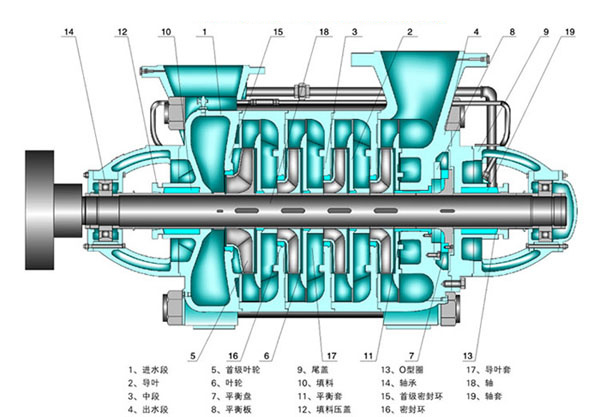

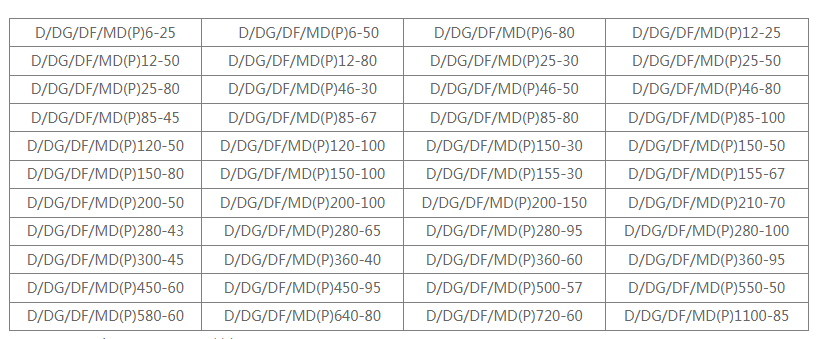

product description MD type mining wear-resistant multi-stage centrifugal pump is a horizontal single-suction multi-stage centrifugal pump, which adopts the hydraulic model of high-efficiency and energy-saving products recommended by the state, and occupies a leading position in technology in the industry. It has the advantages of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance, etc. This type of multi-stage centrifugal pump for mining is used to transport neutral mineral water (particle size less than 0.5 mm) with a solid particle content of not more than 1.5% and other similar sewage. Steel plants, mine drainage, sewage transportation and other occasions. Performance parameters Model meaning and applicable conditions of MD wear-resistant multi-stage centrifugal pump for mining: MD155-67x9 MD—is a multi-stage centrifugal pump for mining 155—The design point flow of the pump is 155m3/h 67 - is the pump single-stage design point head is 67m 9—is the number of stages of the pump is 9  1. Under the condition of clean water (with solid particles less than 0.1%), the efficiency will not drop by more than 6% after running for 5000h without overhaul; 2. Under the condition of sewage containing solid particles below 0.1% to 1%, running for 3000h without overhaul, the efficiency drop does not exceed 5%; 3. Under the condition of sewage containing solid particles of 1-.5%, the efficiency will not drop by more than 6% if it runs for 2000h without major repairs. Structural characteristics of MD type wear-resistant multi-stage centrifugal pump for mining: The stator part is mainly composed of the front section, the middle section, the guide vane, the rear section, the bearing frame and the balance chamber cover. The parts are connected with the rod and the nut. The front section and the rear section are fixed on the pump seat with bolts and nuts. The rotor parts are mainly made of impeller, impeller block, balance block, balance disc and shaft sleeve parts are tightened with small round nuts, and are fixed on the shaft with flat keys to prevent rotation. The entire rotor is supported on bearings at both ends. The rotor is directly connected to the motor with an elastic pin coupling. In order to compensate for the expansion, a toothed pad is installed between the last stage and the balance sleeve, which should be replaced when the pump is overhauled. The multi-stage centrifugal pump for wear-resistant mining adopts a balance plate hydraulic balance device that can completely and automatically balance the axial force. The device consists of four parts: balance plate, balance plate, balance sleeve and balance block. The rotor part of the MD type mining multistage centrifugal pump is mainly composed of the shaft and the impeller, shaft sleeve, balance disc and other parts installed on the shaft. The number of impellers depends on the number of stages of the pump. The parts on the shaft are fastened with a flat key and a shaft nut to be integrated with the shaft. The entire rotor is supported by rolling bearings or sliding bearings at both ends. The bearings are determined according to different models, and none of them bear the axial force. The axial force is balanced by the balance disc. During the operation of the pump, the rotor is allowed to swim axially in the pump casing, and radial ball bearings cannot be used. The rolling bearing is lubricated with oil, the sliding bearing is lubricated with thin oil, and the oil ring is used for self-lubrication, and the circulating water is used for cooling. The sealing surfaces between the water inlet section, middle section and water outlet section of the pump are all sealed with molybdenum disulfide grease, and a sealing ring and guide vane sleeve are installed between the rotor part and the fixed part for sealing. When the degree of wear and tear has affected the working performance of the pump, it should be replaced. The sealing forms of mining multistage centrifugal pumps include mechanical seals and packing seals. When the pump is sealed with packing, the position of the packing ring should be correct, the tightness of the packing must be appropriate, and it is advisable that the liquid can seep drop by drop. The various sealing elements of the pump are installed in the sealing cavity, and the cavity should be filled with water of a certain pressure, and the water sealing, water cooling or water lubrication are optional. A replaceable bushing is installed at the shaft seal to protect the pump shaft. The rotation direction of this type of mining multi-stage centrifugal pump is clockwise when viewed from the direction of the original motor. Instructions for starting the pump:

1. Under the condition of clean water (with solid particles less than 0.1%), the efficiency will not drop by more than 6% after running for 5000h without overhaul; 2. Under the condition of sewage containing solid particles below 0.1% to 1%, running for 3000h without overhaul, the efficiency drop does not exceed 5%; 3. Under the condition of sewage containing solid particles of 1-.5%, the efficiency will not drop by more than 6% if it runs for 2000h without major repairs. Structural characteristics of MD type wear-resistant multi-stage centrifugal pump for mining: The stator part is mainly composed of the front section, the middle section, the guide vane, the rear section, the bearing frame and the balance chamber cover. The parts are connected with the rod and the nut. The front section and the rear section are fixed on the pump seat with bolts and nuts. The rotor parts are mainly made of impeller, impeller block, balance block, balance disc and shaft sleeve parts are tightened with small round nuts, and are fixed on the shaft with flat keys to prevent rotation. The entire rotor is supported on bearings at both ends. The rotor is directly connected to the motor with an elastic pin coupling. In order to compensate for the expansion, a toothed pad is installed between the last stage and the balance sleeve, which should be replaced when the pump is overhauled. The multi-stage centrifugal pump for wear-resistant mining adopts a balance plate hydraulic balance device that can completely and automatically balance the axial force. The device consists of four parts: balance plate, balance plate, balance sleeve and balance block. The rotor part of the MD type mining multistage centrifugal pump is mainly composed of the shaft and the impeller, shaft sleeve, balance disc and other parts installed on the shaft. The number of impellers depends on the number of stages of the pump. The parts on the shaft are fastened with a flat key and a shaft nut to be integrated with the shaft. The entire rotor is supported by rolling bearings or sliding bearings at both ends. The bearings are determined according to different models, and none of them bear the axial force. The axial force is balanced by the balance disc. During the operation of the pump, the rotor is allowed to swim axially in the pump casing, and radial ball bearings cannot be used. The rolling bearing is lubricated with oil, the sliding bearing is lubricated with thin oil, and the oil ring is used for self-lubrication, and the circulating water is used for cooling. The sealing surfaces between the water inlet section, middle section and water outlet section of the pump are all sealed with molybdenum disulfide grease, and a sealing ring and guide vane sleeve are installed between the rotor part and the fixed part for sealing. When the degree of wear and tear has affected the working performance of the pump, it should be replaced. The sealing forms of mining multistage centrifugal pumps include mechanical seals and packing seals. When the pump is sealed with packing, the position of the packing ring should be correct, the tightness of the packing must be appropriate, and it is advisable that the liquid can seep drop by drop. The various sealing elements of the pump are installed in the sealing cavity, and the cavity should be filled with water of a certain pressure, and the water sealing, water cooling or water lubrication are optional. A replaceable bushing is installed at the shaft seal to protect the pump shaft. The rotation direction of this type of mining multi-stage centrifugal pump is clockwise when viewed from the direction of the original motor. Instructions for starting the pump:  Before starting the mining multi-stage centrifugal pump, the pump rotor should be rotated to check whether the rotor is flexible; Check whether the direction of the motor is consistent with the direction of the pump; Open the pump suction valve, close the gate valve of the pump outlet pipeline and the pressure gauge cock, so that the pump is filled with liquid, or use a vacuum system to remove the air in the suction pipe and pump; Check the tightness of the connecting bolts of the pump and the motor and the safety around the pump, so that the pump is ready to start; Start the motor. After the pump runs normally, open the pressure gauge cock and slowly open the pump outlet gate valve until the pressure gauge pointer points to the required pressure (control the pump's given lift according to the outlet pressure gauge reading).

Before starting the mining multi-stage centrifugal pump, the pump rotor should be rotated to check whether the rotor is flexible; Check whether the direction of the motor is consistent with the direction of the pump; Open the pump suction valve, close the gate valve of the pump outlet pipeline and the pressure gauge cock, so that the pump is filled with liquid, or use a vacuum system to remove the air in the suction pipe and pump; Check the tightness of the connecting bolts of the pump and the motor and the safety around the pump, so that the pump is ready to start; Start the motor. After the pump runs normally, open the pressure gauge cock and slowly open the pump outlet gate valve until the pressure gauge pointer points to the required pressure (control the pump's given lift according to the outlet pressure gauge reading).  Operation The wear-resistant multi-stage centrifugal pump for mining uses the balance mechanism in the pump to balance the axial force. The balance liquid flows out from the balance device. The balance liquid is connected to the water inlet section from the balance water pipe, or a short pipe is designed in the balance room. The tube flows out of the pump. In order to ensure the normal operation of the pump, the balance water pipe must not be blocked; In the process of starting and running, you must pay attention to observe the meter readings, whether the bearing heating, packing leakage and heating, and the vibration and sound of the pump are normal. If any abnormal situation is found, it should be dealt with in time; The change of bearing temperature rise reflects the assembly quality of the pump, the bearing temperature rise shall not be higher than the ambient temperature 35℃, and the maximum bearing temperature shall not be higher than 75℃; There is a certain axial movement of the pump rotor during operation, and the axial movement should be within the allowable range, and the clearance value between the end faces of the motor and the two couplings of the water pump should be guaranteed; During the operation of the pump, the wear of the impeller, sealing ring, guide vane sleeve, shaft sleeve, balance disc and other parts should be checked regularly. If the wear is too large, it should be replaced in time. Stop Before shutting down, the pressure gauge cock should be closed, and the outlet gate valve should be closed slowly. After the outlet valve is closed, the motor should be shut down. After the pump has stopped stably, the suction valve of the pump should be closed; the water in the pump should be released. Cleaned and oiled, packaged for storage.

Operation The wear-resistant multi-stage centrifugal pump for mining uses the balance mechanism in the pump to balance the axial force. The balance liquid flows out from the balance device. The balance liquid is connected to the water inlet section from the balance water pipe, or a short pipe is designed in the balance room. The tube flows out of the pump. In order to ensure the normal operation of the pump, the balance water pipe must not be blocked; In the process of starting and running, you must pay attention to observe the meter readings, whether the bearing heating, packing leakage and heating, and the vibration and sound of the pump are normal. If any abnormal situation is found, it should be dealt with in time; The change of bearing temperature rise reflects the assembly quality of the pump, the bearing temperature rise shall not be higher than the ambient temperature 35℃, and the maximum bearing temperature shall not be higher than 75℃; There is a certain axial movement of the pump rotor during operation, and the axial movement should be within the allowable range, and the clearance value between the end faces of the motor and the two couplings of the water pump should be guaranteed; During the operation of the pump, the wear of the impeller, sealing ring, guide vane sleeve, shaft sleeve, balance disc and other parts should be checked regularly. If the wear is too large, it should be replaced in time. Stop Before shutting down, the pressure gauge cock should be closed, and the outlet gate valve should be closed slowly. After the outlet valve is closed, the motor should be shut down. After the pump has stopped stably, the suction valve of the pump should be closed; the water in the pump should be released. Cleaned and oiled, packaged for storage.

Slurry Pumping Systems,

DG type pump,

Ro Booster Pump,

Horizontal pipeline centrifugal pump,

- ZJQ pump,

Instant Hot Water Circulating Pump,

Quarter Turn Electric Actuator,

Heavy-duty pump,

Diaphragm Mud Pump,

Cri Mud Pump,

1. Under the condition of clean water (with solid particles less than 0.1%), the efficiency will not drop by more than 6% after running for 5000h without overhaul; 2. Under the condition of sewage containing solid particles below 0.1% to 1%, running for 3000h without overhaul, the efficiency drop does not exceed 5%; 3. Under the condition of sewage containing solid particles of 1-.5%, the efficiency will not drop by more than 6% if it runs for 2000h without major repairs. Structural characteristics of MD type wear-resistant multi-stage centrifugal pump for mining: The stator part is mainly composed of the front section, the middle section, the guide vane, the rear section, the bearing frame and the balance chamber cover. The parts are connected with the rod and the nut. The front section and the rear section are fixed on the pump seat with bolts and nuts. The rotor parts are mainly made of impeller, impeller block, balance block, balance disc and shaft sleeve parts are tightened with small round nuts, and are fixed on the shaft with flat keys to prevent rotation. The entire rotor is supported on bearings at both ends. The rotor is directly connected to the motor with an elastic pin coupling. In order to compensate for the expansion, a toothed pad is installed between the last stage and the balance sleeve, which should be replaced when the pump is overhauled. The multi-stage centrifugal pump for wear-resistant mining adopts a balance plate hydraulic balance device that can completely and automatically balance the axial force. The device consists of four parts: balance plate, balance plate, balance sleeve and balance block. The rotor part of the MD type mining multistage centrifugal pump is mainly composed of the shaft and the impeller, shaft sleeve, balance disc and other parts installed on the shaft. The number of impellers depends on the number of stages of the pump. The parts on the shaft are fastened with a flat key and a shaft nut to be integrated with the shaft. The entire rotor is supported by rolling bearings or sliding bearings at both ends. The bearings are determined according to different models, and none of them bear the axial force. The axial force is balanced by the balance disc. During the operation of the pump, the rotor is allowed to swim axially in the pump casing, and radial ball bearings cannot be used. The rolling bearing is lubricated with oil, the sliding bearing is lubricated with thin oil, and the oil ring is used for self-lubrication, and the circulating water is used for cooling. The sealing surfaces between the water inlet section, middle section and water outlet section of the pump are all sealed with molybdenum disulfide grease, and a sealing ring and guide vane sleeve are installed between the rotor part and the fixed part for sealing. When the degree of wear and tear has affected the working performance of the pump, it should be replaced. The sealing forms of mining multistage centrifugal pumps include mechanical seals and packing seals. When the pump is sealed with packing, the position of the packing ring should be correct, the tightness of the packing must be appropriate, and it is advisable that the liquid can seep drop by drop. The various sealing elements of the pump are installed in the sealing cavity, and the cavity should be filled with water of a certain pressure, and the water sealing, water cooling or water lubrication are optional. A replaceable bushing is installed at the shaft seal to protect the pump shaft. The rotation direction of this type of mining multi-stage centrifugal pump is clockwise when viewed from the direction of the original motor. Instructions for starting the pump:

1. Under the condition of clean water (with solid particles less than 0.1%), the efficiency will not drop by more than 6% after running for 5000h without overhaul; 2. Under the condition of sewage containing solid particles below 0.1% to 1%, running for 3000h without overhaul, the efficiency drop does not exceed 5%; 3. Under the condition of sewage containing solid particles of 1-.5%, the efficiency will not drop by more than 6% if it runs for 2000h without major repairs. Structural characteristics of MD type wear-resistant multi-stage centrifugal pump for mining: The stator part is mainly composed of the front section, the middle section, the guide vane, the rear section, the bearing frame and the balance chamber cover. The parts are connected with the rod and the nut. The front section and the rear section are fixed on the pump seat with bolts and nuts. The rotor parts are mainly made of impeller, impeller block, balance block, balance disc and shaft sleeve parts are tightened with small round nuts, and are fixed on the shaft with flat keys to prevent rotation. The entire rotor is supported on bearings at both ends. The rotor is directly connected to the motor with an elastic pin coupling. In order to compensate for the expansion, a toothed pad is installed between the last stage and the balance sleeve, which should be replaced when the pump is overhauled. The multi-stage centrifugal pump for wear-resistant mining adopts a balance plate hydraulic balance device that can completely and automatically balance the axial force. The device consists of four parts: balance plate, balance plate, balance sleeve and balance block. The rotor part of the MD type mining multistage centrifugal pump is mainly composed of the shaft and the impeller, shaft sleeve, balance disc and other parts installed on the shaft. The number of impellers depends on the number of stages of the pump. The parts on the shaft are fastened with a flat key and a shaft nut to be integrated with the shaft. The entire rotor is supported by rolling bearings or sliding bearings at both ends. The bearings are determined according to different models, and none of them bear the axial force. The axial force is balanced by the balance disc. During the operation of the pump, the rotor is allowed to swim axially in the pump casing, and radial ball bearings cannot be used. The rolling bearing is lubricated with oil, the sliding bearing is lubricated with thin oil, and the oil ring is used for self-lubrication, and the circulating water is used for cooling. The sealing surfaces between the water inlet section, middle section and water outlet section of the pump are all sealed with molybdenum disulfide grease, and a sealing ring and guide vane sleeve are installed between the rotor part and the fixed part for sealing. When the degree of wear and tear has affected the working performance of the pump, it should be replaced. The sealing forms of mining multistage centrifugal pumps include mechanical seals and packing seals. When the pump is sealed with packing, the position of the packing ring should be correct, the tightness of the packing must be appropriate, and it is advisable that the liquid can seep drop by drop. The various sealing elements of the pump are installed in the sealing cavity, and the cavity should be filled with water of a certain pressure, and the water sealing, water cooling or water lubrication are optional. A replaceable bushing is installed at the shaft seal to protect the pump shaft. The rotation direction of this type of mining multi-stage centrifugal pump is clockwise when viewed from the direction of the original motor. Instructions for starting the pump:  Before starting the mining multi-stage centrifugal pump, the pump rotor should be rotated to check whether the rotor is flexible; Check whether the direction of the motor is consistent with the direction of the pump; Open the pump suction valve, close the gate valve of the pump outlet pipeline and the pressure gauge cock, so that the pump is filled with liquid, or use a vacuum system to remove the air in the suction pipe and pump; Check the tightness of the connecting bolts of the pump and the motor and the safety around the pump, so that the pump is ready to start; Start the motor. After the pump runs normally, open the pressure gauge cock and slowly open the pump outlet gate valve until the pressure gauge pointer points to the required pressure (control the pump's given lift according to the outlet pressure gauge reading).

Before starting the mining multi-stage centrifugal pump, the pump rotor should be rotated to check whether the rotor is flexible; Check whether the direction of the motor is consistent with the direction of the pump; Open the pump suction valve, close the gate valve of the pump outlet pipeline and the pressure gauge cock, so that the pump is filled with liquid, or use a vacuum system to remove the air in the suction pipe and pump; Check the tightness of the connecting bolts of the pump and the motor and the safety around the pump, so that the pump is ready to start; Start the motor. After the pump runs normally, open the pressure gauge cock and slowly open the pump outlet gate valve until the pressure gauge pointer points to the required pressure (control the pump's given lift according to the outlet pressure gauge reading).  Operation The wear-resistant multi-stage centrifugal pump for mining uses the balance mechanism in the pump to balance the axial force. The balance liquid flows out from the balance device. The balance liquid is connected to the water inlet section from the balance water pipe, or a short pipe is designed in the balance room. The tube flows out of the pump. In order to ensure the normal operation of the pump, the balance water pipe must not be blocked; In the process of starting and running, you must pay attention to observe the meter readings, whether the bearing heating, packing leakage and heating, and the vibration and sound of the pump are normal. If any abnormal situation is found, it should be dealt with in time; The change of bearing temperature rise reflects the assembly quality of the pump, the bearing temperature rise shall not be higher than the ambient temperature 35℃, and the maximum bearing temperature shall not be higher than 75℃; There is a certain axial movement of the pump rotor during operation, and the axial movement should be within the allowable range, and the clearance value between the end faces of the motor and the two couplings of the water pump should be guaranteed; During the operation of the pump, the wear of the impeller, sealing ring, guide vane sleeve, shaft sleeve, balance disc and other parts should be checked regularly. If the wear is too large, it should be replaced in time. Stop Before shutting down, the pressure gauge cock should be closed, and the outlet gate valve should be closed slowly. After the outlet valve is closed, the motor should be shut down. After the pump has stopped stably, the suction valve of the pump should be closed; the water in the pump should be released. Cleaned and oiled, packaged for storage.

Operation The wear-resistant multi-stage centrifugal pump for mining uses the balance mechanism in the pump to balance the axial force. The balance liquid flows out from the balance device. The balance liquid is connected to the water inlet section from the balance water pipe, or a short pipe is designed in the balance room. The tube flows out of the pump. In order to ensure the normal operation of the pump, the balance water pipe must not be blocked; In the process of starting and running, you must pay attention to observe the meter readings, whether the bearing heating, packing leakage and heating, and the vibration and sound of the pump are normal. If any abnormal situation is found, it should be dealt with in time; The change of bearing temperature rise reflects the assembly quality of the pump, the bearing temperature rise shall not be higher than the ambient temperature 35℃, and the maximum bearing temperature shall not be higher than 75℃; There is a certain axial movement of the pump rotor during operation, and the axial movement should be within the allowable range, and the clearance value between the end faces of the motor and the two couplings of the water pump should be guaranteed; During the operation of the pump, the wear of the impeller, sealing ring, guide vane sleeve, shaft sleeve, balance disc and other parts should be checked regularly. If the wear is too large, it should be replaced in time. Stop Before shutting down, the pressure gauge cock should be closed, and the outlet gate valve should be closed slowly. After the outlet valve is closed, the motor should be shut down. After the pump has stopped stably, the suction valve of the pump should be closed; the water in the pump should be released. Cleaned and oiled, packaged for storage.