Products Details

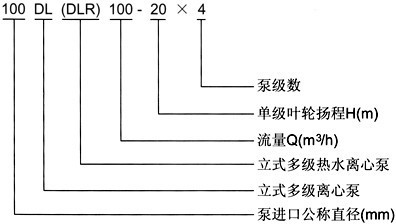

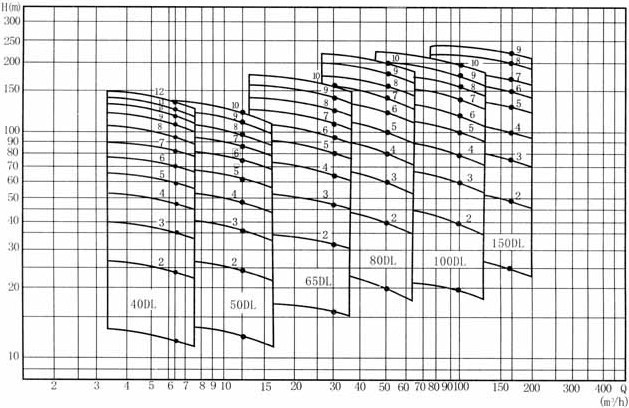

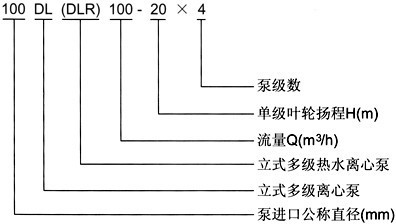

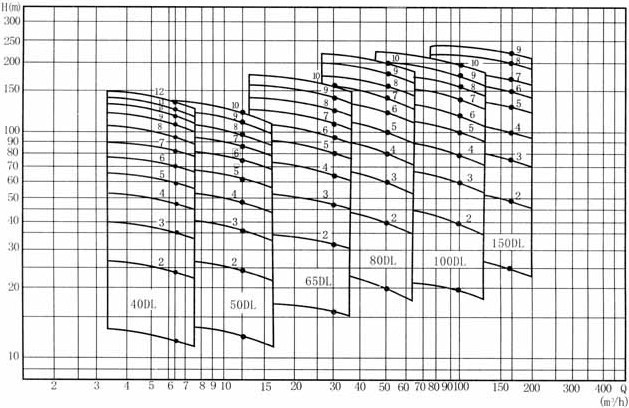

Product Description DL type vertical multistage centrifugal pump (low speed n=1450r/min) is a new centrifugal pump products. Centrifugal pumps are used to transport media that do not contain hard particles and whose physical and chemical properties are similar to water. The flow range is 2~2003/h, the lift range is 23~230mm, the matching power range is 1.5~220KW, and the diameter range is φ40~φ200m. The outlet of the same pump can be set with 1 to 5 outlets. DL vertical multistage centrifugal pump is mainly used for high-rise building domestic water supply, fire constant pressure water supply, automatic spray water, automatic water curtain water supply, etc. Water for various production processes, etc. The operating temperature of the medium of DL type vertical multistage centrifugal pump does not exceed 80℃, and the operating temperature of DLR type vertical multistage centrifugal pump does not exceed 120℃. Performance Parameters DL type vertical multistage centrifugal pump model meaning: Example: 80DL(DLR)×4 80-nominal diameter of pump suction port (mm) DL-Vertical Multistage Segmented Centrifugal Pump DLR-Vertical Multistage Segmented Hot Water Centrifugal Pump 4- Pump stages  DL type vertical multistage centrifugal pump working conditions and product features:

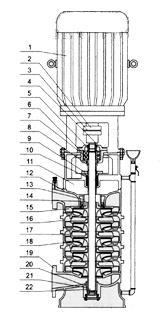

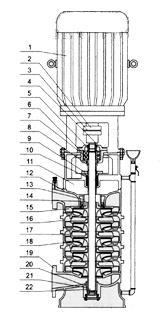

DL type vertical multistage centrifugal pump working conditions and product features:  Working conditions: 1. The medium used in the DL vertical multistage centrifugal pump should be similar to water, with a kinematic viscosity <150mm2/s, and no hard particles and no corrosive properties; 2. The altitude of the environment used by the vertical multi-stage centrifugal pump is less than 1000 meters. When it exceeds, it should be submitted in the order, so that the factory can provide you with more reliable products; 3. The use temperature of the medium is -15℃~120℃; 4. The maximum system working pressure is less than or equal to 2.5MPa; 5. The ambient temperature should be lower than 40°C, and the relative humidity should be lower than 95%. Features: 1. DL vertical multi-stage pump has compact structure, small volume and beautiful appearance. Its vertical structure determines that the installation area is small, and its center of gravity coincides with the center of the pump foot, thus enhancing the running stability and service life of the pump. 2. The suction port and the discharge port of the DL vertical multi-stage pump are horizontal, which simplifies the connection of the pipeline. 3. According to the needs, the suction port and the discharge port can be installed in the same direction or 90°, 180°, 270° in several different directions to meet different connection occasions. 4. The lift of the DL type vertical multistage pump can be increased or decreased according to the needs and combined with the outer diameter of the cutting impeller, without changing the installation area, which is not available in other pumps. 5. The motor is equipped with a rain cover, and the pump can be used outdoors, eliminating the pump room and saving construction costs. 6. The rotor of the DL vertical multistage centrifugal pump has a small deflection, and the 4-pole motor is selected, so the operation is stable, the vibration is small, the noise is low, and the service life is long. DL type vertical multistage centrifugal pump structure diagram and structure description: DL vertical multi-stage centrifugal pump is composed of two parts: motor and pump. The motor is Y-type three-phase asynchronous motor. The pump and motor are connected by coupling. The pump consists of a stator part and a rotor part. The pump stator part is composed of water inlet section, middle section, guide vane, water outlet section, stuffing box and other parts. In order to prevent stator wear, the stator is equipped with sealing ring, balance sleeve, etc., which can be replaced with spare parts after wear. The rotor part consists of shaft, impeller, balance hub, etc. The lower end of the rotor is a water-lubricated bearing, and the upper part is an angular contact ball bearing. Most of the axial force of the DL vertical multistage centrifugal pump is borne by the balance drum, and the remaining small part of the residual axial force is borne by the angular contact ball bearing. The water inlet section, the water outlet section and the joint surface are sealed with paper pads through jointing. The shaft seal adopts packing or mechanical seal, users can choose according to their needs. The direction of rotation of the pump is counterclockwise when viewed from the drive end. 1. DL vertical multi-stage centrifugal water pump has compact structure, small volume, beautiful appearance, small footprint, saving construction costs; 2. The suction port and the water outlet of the DL vertical multistage centrifugal pump are on the same center line, which simplifies the connection of the pipeline; 3. According to the actual situation, the inlet and outlet of the DL vertical multistage centrifugal pump can be assembled in different directions of 90°, 180°, and 270°; 4. According to the actual situation, the outlet of the DL vertical multi-stage centrifugal pump can be assembled into 1~5 outlets to meet the requirements of different lifts on the same pump; DL type vertical multistage centrifugal pump type spectrum:

Working conditions: 1. The medium used in the DL vertical multistage centrifugal pump should be similar to water, with a kinematic viscosity <150mm2/s, and no hard particles and no corrosive properties; 2. The altitude of the environment used by the vertical multi-stage centrifugal pump is less than 1000 meters. When it exceeds, it should be submitted in the order, so that the factory can provide you with more reliable products; 3. The use temperature of the medium is -15℃~120℃; 4. The maximum system working pressure is less than or equal to 2.5MPa; 5. The ambient temperature should be lower than 40°C, and the relative humidity should be lower than 95%. Features: 1. DL vertical multi-stage pump has compact structure, small volume and beautiful appearance. Its vertical structure determines that the installation area is small, and its center of gravity coincides with the center of the pump foot, thus enhancing the running stability and service life of the pump. 2. The suction port and the discharge port of the DL vertical multi-stage pump are horizontal, which simplifies the connection of the pipeline. 3. According to the needs, the suction port and the discharge port can be installed in the same direction or 90°, 180°, 270° in several different directions to meet different connection occasions. 4. The lift of the DL type vertical multistage pump can be increased or decreased according to the needs and combined with the outer diameter of the cutting impeller, without changing the installation area, which is not available in other pumps. 5. The motor is equipped with a rain cover, and the pump can be used outdoors, eliminating the pump room and saving construction costs. 6. The rotor of the DL vertical multistage centrifugal pump has a small deflection, and the 4-pole motor is selected, so the operation is stable, the vibration is small, the noise is low, and the service life is long. DL type vertical multistage centrifugal pump structure diagram and structure description: DL vertical multi-stage centrifugal pump is composed of two parts: motor and pump. The motor is Y-type three-phase asynchronous motor. The pump and motor are connected by coupling. The pump consists of a stator part and a rotor part. The pump stator part is composed of water inlet section, middle section, guide vane, water outlet section, stuffing box and other parts. In order to prevent stator wear, the stator is equipped with sealing ring, balance sleeve, etc., which can be replaced with spare parts after wear. The rotor part consists of shaft, impeller, balance hub, etc. The lower end of the rotor is a water-lubricated bearing, and the upper part is an angular contact ball bearing. Most of the axial force of the DL vertical multistage centrifugal pump is borne by the balance drum, and the remaining small part of the residual axial force is borne by the angular contact ball bearing. The water inlet section, the water outlet section and the joint surface are sealed with paper pads through jointing. The shaft seal adopts packing or mechanical seal, users can choose according to their needs. The direction of rotation of the pump is counterclockwise when viewed from the drive end. 1. DL vertical multi-stage centrifugal water pump has compact structure, small volume, beautiful appearance, small footprint, saving construction costs; 2. The suction port and the water outlet of the DL vertical multistage centrifugal pump are on the same center line, which simplifies the connection of the pipeline; 3. According to the actual situation, the inlet and outlet of the DL vertical multistage centrifugal pump can be assembled in different directions of 90°, 180°, and 270°; 4. According to the actual situation, the outlet of the DL vertical multi-stage centrifugal pump can be assembled into 1~5 outlets to meet the requirements of different lifts on the same pump; DL type vertical multistage centrifugal pump type spectrum:  Pump installation instructions: 1. Check the integrity of the water pump and motor before installation. 2. The pump should be installed as close to the water source as possible. 3. There are two ways to install the pump and the base, one is the rigid connection directly installed on the cement foundation, and the other is the flexible connection installed with the JGD type shock absorber. The specific method is shown in the installation diagram. 4. For direct installation, the pump can be placed on the foundation with a height of 30-40 mm (to be used for filling cement slurry), and then corrected, and the anchor bolts are put on and filled. Cement mortar, after 3 to 5 days of cement drying, recalibrate, after the cement is completely dry, tighten the nuts of the anchor bolts. 5. When installing the pipeline, the inlet and outlet pipelines should have their own supports, and the flange of the pump should not bear excessive pipeline weight. 6. When the pump is used in the occasion with suction, the end of the water inlet pipe should be equipped with a bottom valve, and the inlet and outlet pipes should not have too many bends, and there should be no water leakage or air leakage. 7. It is best to install a filter screen on the inlet pipeline to prevent impurities from entering the interior of the impeller. The effective area of the filter screen should be 3 to 4 times the area of the water inlet pipe to ensure that the liquid The freedom of the body. 8. For the convenience and safety of maintenance and use, install a regulating valve on the inlet and outlet pipelines of the pump and a pressure gauge near the pump outlet to ensure The pump operates within the rated range to ensure the normal operation and service life of the pump. 9. If the inlet needs expansion connection, please choose eccentric reducer pipe joint. Pump start, run and stop: Start: l. The pump is used in the occasion with suction, that is, when the inlet is negative pressure, the inlet pipeline should be filled with water and exhausted or the vacuum pump should be used to divert water to fill the entire pump and inlet pipeline with water. Note that the inlet pipeline must be sealed. There should be no air leakage. 2. Close the gate valve and pressure gauge cock on the outlet pipe to reduce the starting current. 3. Rotate the rotor several times by hand to lubricate the bearing and check whether the impeller and the sealing ring in the pump are rubbed or not. 4. Try to start, the direction of the motor should be in the same direction as the arrow on the pump, and open the pressure gauge cock. 5. When the rotor reaches normal operation and the pressure gauge shows the pressure, gradually open the outlet gate valve and adjust to the required working condition. Operation: 1. When the pump is running, you must pay attention to the reading of the meter, try to make the pump work near the flow head specified on the nameplate, and strictly prevent the operation of large flow. 2. Regularly check that the current value of the motor should not exceed the rated current; 3. The bearing temperature of the pump shall not be higher than 75℃, and shall not exceed the external temperature of 35℃. 4. When the pump starts to run, the packing gland should be loosened, and when the expanded graphite or packing is fully expanded, it should be adjusted to an appropriate level. 5. If the wearing parts are too worn, they should be replaced in time. 6. If any abnormal phenomenon is found, stop the machine immediately to check the cause. Parking: 1. Close the gate regulator on the water outlet pipe and close the vacuum gauge cock. 2. Stop the motor, and then close the pressure gauge cock. 3. If there is a cold season in winter, the liquid in the pump should be drained to avoid freezing and cracking. 4. If the pump is not used for a long time, the pump should be disassembled, cleaned and oiled, and kept properly.

Pump installation instructions: 1. Check the integrity of the water pump and motor before installation. 2. The pump should be installed as close to the water source as possible. 3. There are two ways to install the pump and the base, one is the rigid connection directly installed on the cement foundation, and the other is the flexible connection installed with the JGD type shock absorber. The specific method is shown in the installation diagram. 4. For direct installation, the pump can be placed on the foundation with a height of 30-40 mm (to be used for filling cement slurry), and then corrected, and the anchor bolts are put on and filled. Cement mortar, after 3 to 5 days of cement drying, recalibrate, after the cement is completely dry, tighten the nuts of the anchor bolts. 5. When installing the pipeline, the inlet and outlet pipelines should have their own supports, and the flange of the pump should not bear excessive pipeline weight. 6. When the pump is used in the occasion with suction, the end of the water inlet pipe should be equipped with a bottom valve, and the inlet and outlet pipes should not have too many bends, and there should be no water leakage or air leakage. 7. It is best to install a filter screen on the inlet pipeline to prevent impurities from entering the interior of the impeller. The effective area of the filter screen should be 3 to 4 times the area of the water inlet pipe to ensure that the liquid The freedom of the body. 8. For the convenience and safety of maintenance and use, install a regulating valve on the inlet and outlet pipelines of the pump and a pressure gauge near the pump outlet to ensure The pump operates within the rated range to ensure the normal operation and service life of the pump. 9. If the inlet needs expansion connection, please choose eccentric reducer pipe joint. Pump start, run and stop: Start: l. The pump is used in the occasion with suction, that is, when the inlet is negative pressure, the inlet pipeline should be filled with water and exhausted or the vacuum pump should be used to divert water to fill the entire pump and inlet pipeline with water. Note that the inlet pipeline must be sealed. There should be no air leakage. 2. Close the gate valve and pressure gauge cock on the outlet pipe to reduce the starting current. 3. Rotate the rotor several times by hand to lubricate the bearing and check whether the impeller and the sealing ring in the pump are rubbed or not. 4. Try to start, the direction of the motor should be in the same direction as the arrow on the pump, and open the pressure gauge cock. 5. When the rotor reaches normal operation and the pressure gauge shows the pressure, gradually open the outlet gate valve and adjust to the required working condition. Operation: 1. When the pump is running, you must pay attention to the reading of the meter, try to make the pump work near the flow head specified on the nameplate, and strictly prevent the operation of large flow. 2. Regularly check that the current value of the motor should not exceed the rated current; 3. The bearing temperature of the pump shall not be higher than 75℃, and shall not exceed the external temperature of 35℃. 4. When the pump starts to run, the packing gland should be loosened, and when the expanded graphite or packing is fully expanded, it should be adjusted to an appropriate level. 5. If the wearing parts are too worn, they should be replaced in time. 6. If any abnormal phenomenon is found, stop the machine immediately to check the cause. Parking: 1. Close the gate regulator on the water outlet pipe and close the vacuum gauge cock. 2. Stop the motor, and then close the pressure gauge cock. 3. If there is a cold season in winter, the liquid in the pump should be drained to avoid freezing and cracking. 4. If the pump is not used for a long time, the pump should be disassembled, cleaned and oiled, and kept properly.

Hot Water Recirculating Pump Without Return Line,

Protective Sleeves,

Impurity Pump,

High Pressure Water Fountain Pump,

Dredging A Pond With A Trash Pump,

High Pressure Slurry Pump,

Industrial High Pressure Water Pump,

Under Sink Recirculating Pump,

High Pressure Hydraulic Pump,

Water Supply Equipment,

DL type vertical multistage centrifugal pump working conditions and product features:

DL type vertical multistage centrifugal pump working conditions and product features:  Working conditions: 1. The medium used in the DL vertical multistage centrifugal pump should be similar to water, with a kinematic viscosity <150mm2/s, and no hard particles and no corrosive properties; 2. The altitude of the environment used by the vertical multi-stage centrifugal pump is less than 1000 meters. When it exceeds, it should be submitted in the order, so that the factory can provide you with more reliable products; 3. The use temperature of the medium is -15℃~120℃; 4. The maximum system working pressure is less than or equal to 2.5MPa; 5. The ambient temperature should be lower than 40°C, and the relative humidity should be lower than 95%. Features: 1. DL vertical multi-stage pump has compact structure, small volume and beautiful appearance. Its vertical structure determines that the installation area is small, and its center of gravity coincides with the center of the pump foot, thus enhancing the running stability and service life of the pump. 2. The suction port and the discharge port of the DL vertical multi-stage pump are horizontal, which simplifies the connection of the pipeline. 3. According to the needs, the suction port and the discharge port can be installed in the same direction or 90°, 180°, 270° in several different directions to meet different connection occasions. 4. The lift of the DL type vertical multistage pump can be increased or decreased according to the needs and combined with the outer diameter of the cutting impeller, without changing the installation area, which is not available in other pumps. 5. The motor is equipped with a rain cover, and the pump can be used outdoors, eliminating the pump room and saving construction costs. 6. The rotor of the DL vertical multistage centrifugal pump has a small deflection, and the 4-pole motor is selected, so the operation is stable, the vibration is small, the noise is low, and the service life is long. DL type vertical multistage centrifugal pump structure diagram and structure description: DL vertical multi-stage centrifugal pump is composed of two parts: motor and pump. The motor is Y-type three-phase asynchronous motor. The pump and motor are connected by coupling. The pump consists of a stator part and a rotor part. The pump stator part is composed of water inlet section, middle section, guide vane, water outlet section, stuffing box and other parts. In order to prevent stator wear, the stator is equipped with sealing ring, balance sleeve, etc., which can be replaced with spare parts after wear. The rotor part consists of shaft, impeller, balance hub, etc. The lower end of the rotor is a water-lubricated bearing, and the upper part is an angular contact ball bearing. Most of the axial force of the DL vertical multistage centrifugal pump is borne by the balance drum, and the remaining small part of the residual axial force is borne by the angular contact ball bearing. The water inlet section, the water outlet section and the joint surface are sealed with paper pads through jointing. The shaft seal adopts packing or mechanical seal, users can choose according to their needs. The direction of rotation of the pump is counterclockwise when viewed from the drive end. 1. DL vertical multi-stage centrifugal water pump has compact structure, small volume, beautiful appearance, small footprint, saving construction costs; 2. The suction port and the water outlet of the DL vertical multistage centrifugal pump are on the same center line, which simplifies the connection of the pipeline; 3. According to the actual situation, the inlet and outlet of the DL vertical multistage centrifugal pump can be assembled in different directions of 90°, 180°, and 270°; 4. According to the actual situation, the outlet of the DL vertical multi-stage centrifugal pump can be assembled into 1~5 outlets to meet the requirements of different lifts on the same pump; DL type vertical multistage centrifugal pump type spectrum:

Working conditions: 1. The medium used in the DL vertical multistage centrifugal pump should be similar to water, with a kinematic viscosity <150mm2/s, and no hard particles and no corrosive properties; 2. The altitude of the environment used by the vertical multi-stage centrifugal pump is less than 1000 meters. When it exceeds, it should be submitted in the order, so that the factory can provide you with more reliable products; 3. The use temperature of the medium is -15℃~120℃; 4. The maximum system working pressure is less than or equal to 2.5MPa; 5. The ambient temperature should be lower than 40°C, and the relative humidity should be lower than 95%. Features: 1. DL vertical multi-stage pump has compact structure, small volume and beautiful appearance. Its vertical structure determines that the installation area is small, and its center of gravity coincides with the center of the pump foot, thus enhancing the running stability and service life of the pump. 2. The suction port and the discharge port of the DL vertical multi-stage pump are horizontal, which simplifies the connection of the pipeline. 3. According to the needs, the suction port and the discharge port can be installed in the same direction or 90°, 180°, 270° in several different directions to meet different connection occasions. 4. The lift of the DL type vertical multistage pump can be increased or decreased according to the needs and combined with the outer diameter of the cutting impeller, without changing the installation area, which is not available in other pumps. 5. The motor is equipped with a rain cover, and the pump can be used outdoors, eliminating the pump room and saving construction costs. 6. The rotor of the DL vertical multistage centrifugal pump has a small deflection, and the 4-pole motor is selected, so the operation is stable, the vibration is small, the noise is low, and the service life is long. DL type vertical multistage centrifugal pump structure diagram and structure description: DL vertical multi-stage centrifugal pump is composed of two parts: motor and pump. The motor is Y-type three-phase asynchronous motor. The pump and motor are connected by coupling. The pump consists of a stator part and a rotor part. The pump stator part is composed of water inlet section, middle section, guide vane, water outlet section, stuffing box and other parts. In order to prevent stator wear, the stator is equipped with sealing ring, balance sleeve, etc., which can be replaced with spare parts after wear. The rotor part consists of shaft, impeller, balance hub, etc. The lower end of the rotor is a water-lubricated bearing, and the upper part is an angular contact ball bearing. Most of the axial force of the DL vertical multistage centrifugal pump is borne by the balance drum, and the remaining small part of the residual axial force is borne by the angular contact ball bearing. The water inlet section, the water outlet section and the joint surface are sealed with paper pads through jointing. The shaft seal adopts packing or mechanical seal, users can choose according to their needs. The direction of rotation of the pump is counterclockwise when viewed from the drive end. 1. DL vertical multi-stage centrifugal water pump has compact structure, small volume, beautiful appearance, small footprint, saving construction costs; 2. The suction port and the water outlet of the DL vertical multistage centrifugal pump are on the same center line, which simplifies the connection of the pipeline; 3. According to the actual situation, the inlet and outlet of the DL vertical multistage centrifugal pump can be assembled in different directions of 90°, 180°, and 270°; 4. According to the actual situation, the outlet of the DL vertical multi-stage centrifugal pump can be assembled into 1~5 outlets to meet the requirements of different lifts on the same pump; DL type vertical multistage centrifugal pump type spectrum:  Pump installation instructions: 1. Check the integrity of the water pump and motor before installation. 2. The pump should be installed as close to the water source as possible. 3. There are two ways to install the pump and the base, one is the rigid connection directly installed on the cement foundation, and the other is the flexible connection installed with the JGD type shock absorber. The specific method is shown in the installation diagram. 4. For direct installation, the pump can be placed on the foundation with a height of 30-40 mm (to be used for filling cement slurry), and then corrected, and the anchor bolts are put on and filled. Cement mortar, after 3 to 5 days of cement drying, recalibrate, after the cement is completely dry, tighten the nuts of the anchor bolts. 5. When installing the pipeline, the inlet and outlet pipelines should have their own supports, and the flange of the pump should not bear excessive pipeline weight. 6. When the pump is used in the occasion with suction, the end of the water inlet pipe should be equipped with a bottom valve, and the inlet and outlet pipes should not have too many bends, and there should be no water leakage or air leakage. 7. It is best to install a filter screen on the inlet pipeline to prevent impurities from entering the interior of the impeller. The effective area of the filter screen should be 3 to 4 times the area of the water inlet pipe to ensure that the liquid The freedom of the body. 8. For the convenience and safety of maintenance and use, install a regulating valve on the inlet and outlet pipelines of the pump and a pressure gauge near the pump outlet to ensure The pump operates within the rated range to ensure the normal operation and service life of the pump. 9. If the inlet needs expansion connection, please choose eccentric reducer pipe joint. Pump start, run and stop: Start: l. The pump is used in the occasion with suction, that is, when the inlet is negative pressure, the inlet pipeline should be filled with water and exhausted or the vacuum pump should be used to divert water to fill the entire pump and inlet pipeline with water. Note that the inlet pipeline must be sealed. There should be no air leakage. 2. Close the gate valve and pressure gauge cock on the outlet pipe to reduce the starting current. 3. Rotate the rotor several times by hand to lubricate the bearing and check whether the impeller and the sealing ring in the pump are rubbed or not. 4. Try to start, the direction of the motor should be in the same direction as the arrow on the pump, and open the pressure gauge cock. 5. When the rotor reaches normal operation and the pressure gauge shows the pressure, gradually open the outlet gate valve and adjust to the required working condition. Operation: 1. When the pump is running, you must pay attention to the reading of the meter, try to make the pump work near the flow head specified on the nameplate, and strictly prevent the operation of large flow. 2. Regularly check that the current value of the motor should not exceed the rated current; 3. The bearing temperature of the pump shall not be higher than 75℃, and shall not exceed the external temperature of 35℃. 4. When the pump starts to run, the packing gland should be loosened, and when the expanded graphite or packing is fully expanded, it should be adjusted to an appropriate level. 5. If the wearing parts are too worn, they should be replaced in time. 6. If any abnormal phenomenon is found, stop the machine immediately to check the cause. Parking: 1. Close the gate regulator on the water outlet pipe and close the vacuum gauge cock. 2. Stop the motor, and then close the pressure gauge cock. 3. If there is a cold season in winter, the liquid in the pump should be drained to avoid freezing and cracking. 4. If the pump is not used for a long time, the pump should be disassembled, cleaned and oiled, and kept properly.

Pump installation instructions: 1. Check the integrity of the water pump and motor before installation. 2. The pump should be installed as close to the water source as possible. 3. There are two ways to install the pump and the base, one is the rigid connection directly installed on the cement foundation, and the other is the flexible connection installed with the JGD type shock absorber. The specific method is shown in the installation diagram. 4. For direct installation, the pump can be placed on the foundation with a height of 30-40 mm (to be used for filling cement slurry), and then corrected, and the anchor bolts are put on and filled. Cement mortar, after 3 to 5 days of cement drying, recalibrate, after the cement is completely dry, tighten the nuts of the anchor bolts. 5. When installing the pipeline, the inlet and outlet pipelines should have their own supports, and the flange of the pump should not bear excessive pipeline weight. 6. When the pump is used in the occasion with suction, the end of the water inlet pipe should be equipped with a bottom valve, and the inlet and outlet pipes should not have too many bends, and there should be no water leakage or air leakage. 7. It is best to install a filter screen on the inlet pipeline to prevent impurities from entering the interior of the impeller. The effective area of the filter screen should be 3 to 4 times the area of the water inlet pipe to ensure that the liquid The freedom of the body. 8. For the convenience and safety of maintenance and use, install a regulating valve on the inlet and outlet pipelines of the pump and a pressure gauge near the pump outlet to ensure The pump operates within the rated range to ensure the normal operation and service life of the pump. 9. If the inlet needs expansion connection, please choose eccentric reducer pipe joint. Pump start, run and stop: Start: l. The pump is used in the occasion with suction, that is, when the inlet is negative pressure, the inlet pipeline should be filled with water and exhausted or the vacuum pump should be used to divert water to fill the entire pump and inlet pipeline with water. Note that the inlet pipeline must be sealed. There should be no air leakage. 2. Close the gate valve and pressure gauge cock on the outlet pipe to reduce the starting current. 3. Rotate the rotor several times by hand to lubricate the bearing and check whether the impeller and the sealing ring in the pump are rubbed or not. 4. Try to start, the direction of the motor should be in the same direction as the arrow on the pump, and open the pressure gauge cock. 5. When the rotor reaches normal operation and the pressure gauge shows the pressure, gradually open the outlet gate valve and adjust to the required working condition. Operation: 1. When the pump is running, you must pay attention to the reading of the meter, try to make the pump work near the flow head specified on the nameplate, and strictly prevent the operation of large flow. 2. Regularly check that the current value of the motor should not exceed the rated current; 3. The bearing temperature of the pump shall not be higher than 75℃, and shall not exceed the external temperature of 35℃. 4. When the pump starts to run, the packing gland should be loosened, and when the expanded graphite or packing is fully expanded, it should be adjusted to an appropriate level. 5. If the wearing parts are too worn, they should be replaced in time. 6. If any abnormal phenomenon is found, stop the machine immediately to check the cause. Parking: 1. Close the gate regulator on the water outlet pipe and close the vacuum gauge cock. 2. Stop the motor, and then close the pressure gauge cock. 3. If there is a cold season in winter, the liquid in the pump should be drained to avoid freezing and cracking. 4. If the pump is not used for a long time, the pump should be disassembled, cleaned and oiled, and kept properly.